McCormick-Deering 22-36:

The "Farmer Engineered" Powerhouse

by Kevin Stephenson

Originally published in

Gas Engine Magazine

Volume 20, Jan/Feb 1985

Kevin Stephenson is a senior contributor to McCormick-Deering.com and has written a number of articles in past years for "Gas Engine Magazine". With Kevin's permission, we are pleased to be able

to offer these articles for you to enjoy. The "Farmer Engineered" Powerhouse is the first in the series.

From your friends at McCormick-Deering.com

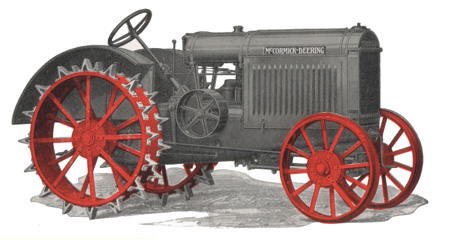

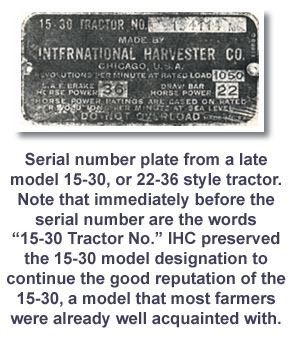

The McCormick-Deering 15-30 tractor, as originally built from 1921 to 1934, was a kerosene powered steel-wheeled powerhouse which developed 15 drawbar and 30 brake horsepower, until refinements in 1929 increased the power output to 22 drawbar and 36 brake horsepower. This tractor was referred to throughout its

production run as a 15-30 by IHC as the name 15-30 had become famous with farmers

across the nation. This was a tractor which, along with the famous John Deere "D", made the transition

from horsepower to horsepower complete. The 15-30 and the D were evenly matched, as the D's rated

horsepower was 15-27. The D was a two-cylinder horizontal-engined machine, but the 15-30 was a

four-cylinder vertical.

production run as a 15-30 by IHC as the name 15-30 had become famous with farmers

across the nation. This was a tractor which, along with the famous John Deere "D", made the transition

from horsepower to horsepower complete. The 15-30 and the D were evenly matched, as the D's rated

horsepower was 15-27. The D was a two-cylinder horizontal-engined machine, but the 15-30 was a

four-cylinder vertical.

The late 15-30, or 22-36 style, was one of the workhorses of this country's farm production during World War II, as production of new farm machines came almost to a standstill while the factories were engaged in war production. Many farmers couldn't afford to trade for newer equipment during the depression, and couldn't get it during the war, so that old tractor had to make do. The 22-36 had an IHC-built kerosene model RW 1 1/2 inch carburetor, which had a water-injection attachment, to add water to the intake manifold when the engine began detonating on heavy

loads on kerosene. These tractors burned kerosene fairly well, as long as the engine

temperature was maintained close to the boiling point. Many farmers who owned these tractors

when the depression hit had no choice but to continue to use them until times got better, so

most of them looked for ways to improve on the machine, increase its power, and prolong its

usefulness.

loads on kerosene. These tractors burned kerosene fairly well, as long as the engine

temperature was maintained close to the boiling point. Many farmers who owned these tractors

when the depression hit had no choice but to continue to use them until times got better, so

most of them looked for ways to improve on the machine, increase its power, and prolong its

usefulness.

Farmer Engineered Improvement

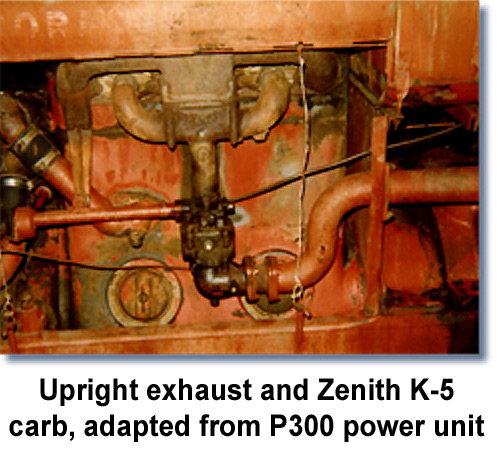

The first change to be made was the switch from kerosene to gasoline operation. Kerosene was cheaper fuel, but it didn't provide as much power as gasoline, and as stated earlier, the engine had to be run much hotter to burn it efficiently. The excess heat, and the side exhaust blowing

fumes in your face when the wind was right, led many farmers to decide there had to be a better

way. The P-300 power units were identical in design to the 22-36 engine, but were equipped with

an upright exhaust, "cold" gasoline manifold, and Zenith K5 carburetor. When farmers discovered

that the parts would interchange, these manifolds and carbs sold like hotcakes. As the changeover

was made, it was necessary to cut a hole in the upper hood sheet to accommodate the exhaust, and

engine had to be run much hotter to burn it efficiently. The excess heat, and the side exhaust blowing

fumes in your face when the wind was right, led many farmers to decide there had to be a better

way. The P-300 power units were identical in design to the 22-36 engine, but were equipped with

an upright exhaust, "cold" gasoline manifold, and Zenith K5 carburetor. When farmers discovered

that the parts would interchange, these manifolds and carbs sold like hotcakes. As the changeover

was made, it was necessary to cut a hole in the upper hood sheet to accommodate the exhaust, and

as the left hood would no longer fold, the side-sheets were removed and replaced by wires to the

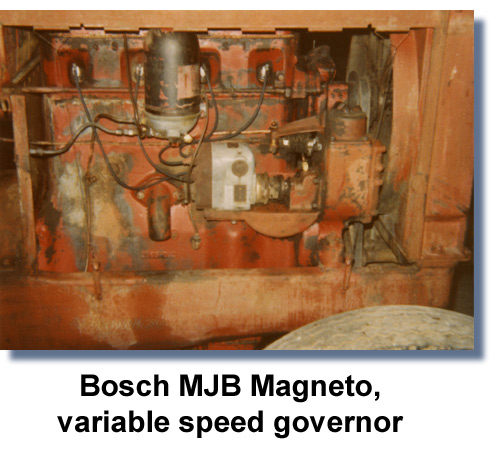

hood latches. This is why the sidesheets are so hard to find today. The P-300 also had a variable

speed governor, as opposed to the 22-36's single-speed governor, and this change came quickly as

it was discovered how much better the variable-speed governor would operate.

as the left hood would no longer fold, the side-sheets were removed and replaced by wires to the

hood latches. This is why the sidesheets are so hard to find today. The P-300 also had a variable

speed governor, as opposed to the 22-36's single-speed governor, and this change came quickly as

it was discovered how much better the variable-speed governor would operate.

(continued at top right column)

From Steel to Rubber

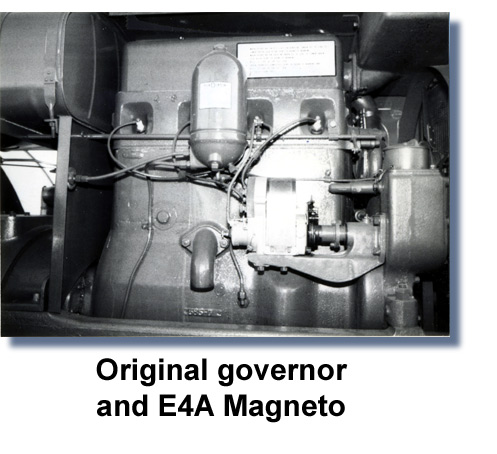

The next step, in most cases, was the conversion from steel wheels to rubber tires. The open-style spade lugs had an aggravating habit of packing dirt inside the lug, and then releasing it at just about the right level to hit you in the face as the wheels turned. Also, the front steel with skid rings were almost impossible to turn in soft ground. The front wheels were cut down, and usually had truck rims installed for ease in tire changing. The rears had large tractor-type rims installed, usually those built by Firestone, who pioneered the application of tractor-tires to Allis-Chalmers tractors in 1932. The French & Hecht company also supplied factory-built pneumatic-tire wheels for IH and other manufacturers, but most farmers had their own wheels remade to save money. The 15-30 was first equipped with a Splitdorff "Dixie" magneto, and later with an International type

E4A high tension magneto with hand-trip impulse. This magneto was very dependable and produced a good,

hot spark. The only drawback to the E4A was its open-type construction, which dictated that it had to

be constantly cleaned and oiled to maintain its performance.

The 15-30 was first equipped with a Splitdorff "Dixie" magneto, and later with an International type

E4A high tension magneto with hand-trip impulse. This magneto was very dependable and produced a good,

hot spark. The only drawback to the E4A was its open-type construction, which dictated that it had to

be constantly cleaned and oiled to maintain its performance.

When the American Bosch type MJB magneto was introduced, many farmers took the E4A out of service in

favor of the totally enclosed, auto-impulse Bosch. Maintenance of the Bosch was minimal, as all the

working parts were kept dirt free.

favor of the totally enclosed, auto-impulse Bosch. Maintenance of the Bosch was minimal, as all the

working parts were kept dirt free.

The 22-36 was further boosted in power by installing high-altitude pistons, which were available for 5000 and 8000-foot altitudes. These pistons were intended for use in higher elevations where the air was thinner, but they increased the compression ratio, and the power output, an many tractors on the Great Plains.

The 22-36 had a U-shaped draw bar with a loop clevis, and the side draft created when turning corners caused the front end to slide for quite a distance before completing the comer. This was solved by the use of a sliding bar attached to a pivot under the tractor to shift the center of draft as the tractor cornered.

When the modifications were completed, the brake horsepower of the "22-36" was boosted from 36 to 50 HP. Drawbar horsepower was also drastically increased with the swing¬ing drawbar and rubber tires.

True Farmer Ingenuity

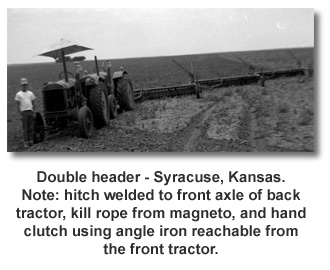

Some farmers, like Ralph Burnett, got the idea to couple two of these tractors together using a hitch also coupled to the steering mechanism on the rear tractor, a remote-control clutch, remote throttle, and a "kill rope" to the magneto lever on the back tractor. Together, these tractors would develop approximately 130 drawbar horsepower, comparable to a 4020 John Deere.

Fuel consumption for a "double-header" at full load was approximately eight gallons per hour gasoline. The units pictured were pulling three fifteen-foot one-way plows apiece, plowing a total width of 76 feet per round, and traveling at 4 1/2 MPH.

Fuel was expensive, but the interest savings from not having to finance new machinery more than paid for the fuel. Ralph Burnett, with FIFTEEN 22-36 tractors and the machinery it took to farm 2700 acres, paid $22.50 in taxes on his machinery in 1970.

We hope you enjoyed Part I of our series of articles from our past GEM articles. Look for our next installment in the coming months.